- 2019-05-30 09:07:51

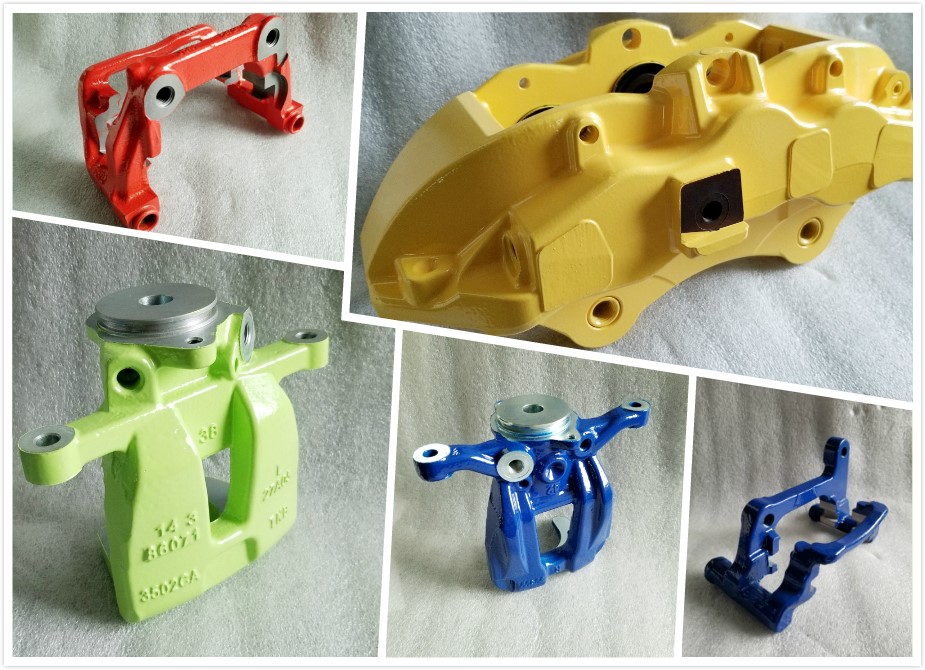

Electrostatic powder spraying is commonly known as "electrostatic spraying."

Electrostatic powder spraying uses a coating machine with an atomizing nozzle (to atomize the paint) and a discharge level (to generate electricity and current) to atomize the paint and apply a charge to it to form an electric field between the electrode and the object to be coated. Painted by electrostatic adsorption.

Main features: spraying method can be manual, automatic or manual + automatic. The spray material is 100% solid powder, the free powder can be recycled, and the recycling rate of the coating can reach 98%. Suspended transportation system with high degree of automation. The coating has few micropores, good anti-corrosion performance, and can be used for thick film spraying at one time.

The electrostatic powder spraying process appeared in the 1960s and is mainly applied to metal surface coating. In the late 1990s, with the development of powder coatings and spraying equipment, it became possible to apply electrostatic powder spraying processes to non-metallic surfaces.